Business Hours (UTC+3)

Mon-Fri: 8 AM - 5 PM

Mon-Fri: 8 AM - 5 PM

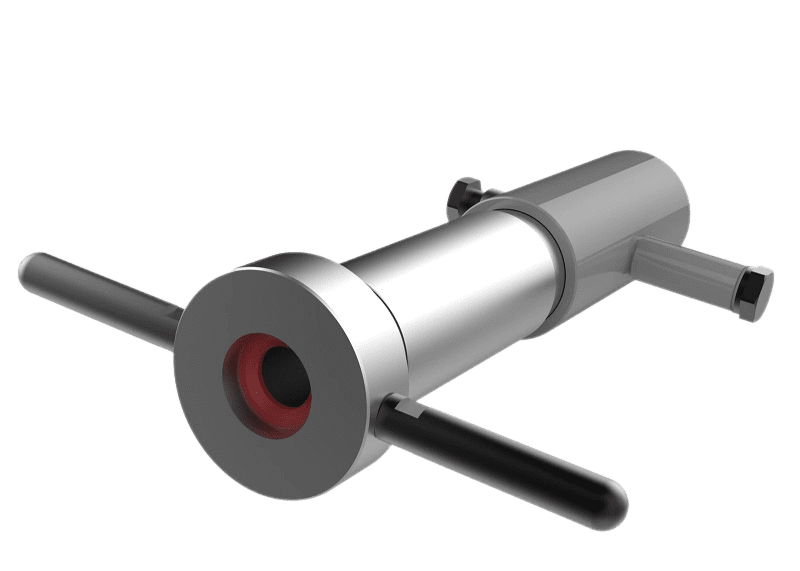

Diaphragm critical flow indicator DICT-50, DICT-100

For measuring gas flow while draining critical discharge through diaphragm with gas emission into atmosphere

By clicking on the button, you consent to the processing of your personal data in accordance with the privacy policy

01

02

Direct equipment manufacturer

We guarantee the quality of our products

Certified equipment

Development according to drawings

Warranty service

Worldwide delivery

DICT-50 or DICT-100 is designed for measuring pressure in a well and may be integrated into a wellhead equipment.

DICT consists of body with a slick tubing thread as per GOST 633-80 on one end. On the other end – metric thread with a recess/seat for a diaphragm/orifice plate which is seated and compressed by a nut and handles. The other end is connected with flare line or welded into the line along with a choke.

A set of DICT has up to 29 diaphragms of various diameters (quantity may be changed upon Client’s request). An orifice of the diaphragm/orifice plate is selected based on specific well rate.

In addition, DICT can be fitted with a measuring tube which can be nippled up directly to DICT. Alternitavely, the tube can be connected using 3.5 inch tubing subs at a required distance. Then, pressure and temperature gauges can be set on the tube, and flow measurements can be taken in the flow section of the tube.

DICT consists of body with a slick tubing thread as per GOST 633-80 on one end. On the other end – metric thread with a recess/seat for a diaphragm/orifice plate which is seated and compressed by a nut and handles. The other end is connected with flare line or welded into the line along with a choke.

A set of DICT has up to 29 diaphragms of various diameters (quantity may be changed upon Client’s request). An orifice of the diaphragm/orifice plate is selected based on specific well rate.

In addition, DICT can be fitted with a measuring tube which can be nippled up directly to DICT. Alternitavely, the tube can be connected using 3.5 inch tubing subs at a required distance. Then, pressure and temperature gauges can be set on the tube, and flow measurements can be taken in the flow section of the tube.

A diaphragm with a small diameter calibrated orifice is installed in the DICT jam nut. Then open the root gate valve, start the well and wait for a steady state, when the pressure and gas temperature upstream of the DICT diaphragm and in the annulus are unchanged with time. The obtained values are recorded in the logbook, after that the well operation is stopped by closing the root gate valve.

Next, a diaphragm with a larger diameter calibrated orifice is installed in the DICT, a stable condition is waited for, pressure and temperature readings are recorded again, and then the well is closed. These operations are repeated 4, 6 or 9 times, depending on the number of available orifices.

To investigate the well with DICT, install an orifice plate on the end of the flare line, directed towards the HFC barn, and tighten the required orifice plate with a nut.

Next, a diaphragm with a larger diameter calibrated orifice is installed in the DICT, a stable condition is waited for, pressure and temperature readings are recorded again, and then the well is closed. These operations are repeated 4, 6 or 9 times, depending on the number of available orifices.

To investigate the well with DICT, install an orifice plate on the end of the flare line, directed towards the HFC barn, and tighten the required orifice plate with a nut.

Principle of operation

Technical specifications

DICT manufacturing options

Photo Gallery

FAQs

The diaphragm critical flow meter is designed for pressures of 35 and 70 MPa. depending on the version.

Yes, we offer a 1 year warranty on the Critical Flow Diaphragm Meter.

To order equipment and consult with our experts, you can contact us by phone, email or fill out the feedback form on our website. Our team will be happy to help you find a solution optimised for your needs.