Business Hours (UTC+3)

Mon-Fri: 8 AM - 5 PM

Mon-Fri: 8 AM - 5 PM

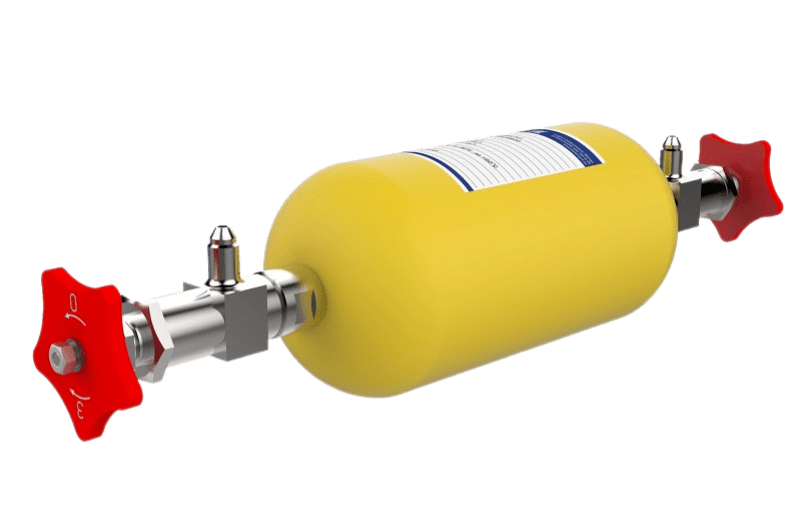

Gas sampler “PGO”

Gas container with nonsplintering metal-composite made bottle for selection, storage, transportation of gases and liquids

By clicking on the button, you consent to the processing of your personal data in accordance with the privacy policy

01

02

Direct equipment manufacturer

We guarantee the quality of our products

Certified equipment

Development according to drawings

Warranty service

Worldwide delivery

Designed for selection, storage and transportation of liquid, gas and condensate under pressure of up to 35 MPa (350 kgf/cm2) at temperature ranging from -60°С to +50°С

H2S Resistant Design (K2 as per GOST)

A distinctive feature of the sampler is a light nonsplintering metal-composite bottle consisting of internal sealed liner made of stainless steel 12H18N10T by method of argon arc welding, and an external pressure shell (“cocoon” type) made of reinforcement threads saturated with adhesive agent. In the neck of the bottle there is a thread for connecting valves to let the analyzed hydrocarbon phase in and out of the bottle.

If requested by Client the sampler can be manufactured having volume of equal to or more than 500 cubic cm. In addition, a transportation case may be provided with seal tags to ensure better comfort while storing and transporting.

H2S Resistant Design (K2 as per GOST)

A distinctive feature of the sampler is a light nonsplintering metal-composite bottle consisting of internal sealed liner made of stainless steel 12H18N10T by method of argon arc welding, and an external pressure shell (“cocoon” type) made of reinforcement threads saturated with adhesive agent. In the neck of the bottle there is a thread for connecting valves to let the analyzed hydrocarbon phase in and out of the bottle.

If requested by Client the sampler can be manufactured having volume of equal to or more than 500 cubic cm. In addition, a transportation case may be provided with seal tags to ensure better comfort while storing and transporting.

When taking a sample from the separator through the sampler, the sample material should be passed through the cylinder (with the valves open) in a volume greater than 5 times the usable volume of the container. Next, close the outlet valve and wait for the desired pressure to be reached before closing the second valve.

The process of transferring the sample material from the sampler to the container is then carried out at a maintained pressure, by displacing the neutral liquid through an open outlet valve. The method used to transfer the sample to the research apparatus is to displace the latter from the container by means of neutral liquid flowing into one of the pressurised valves. The second valve is connected to the research apparatus.

Operating principle

Technical specifications

The use of a wide range of working media (gases) allows the strength characteristics of composite materials to be maximised.

The cylinders provide safety through a shrapnel-free fracture mechanism that, under extreme loads, only loses containment without rupturing the shell or producing shrapnel.

1

The cylinder retains its tightness even after being in an environment with a temperature of 200C for 1 minute.

2

Advantages

They are highly resistant to mechanical damage and naked flame.

Cylinders have high corrosion and chemical resistance, heat and fire resistance.

3

The larger cylinder body size allows 1 to 20 litres of sample to be stored and transported.

5

Cylinders provide up to 5000 withdrawal cycles (charge-discharge).

The total weight of the cylinder is 3-5 times less compared to PGO or KJO type samplers.

4

The service life of the cylinders is extended to 10 years without the need for calibration.

6

8

7

9

Video Presentation

FAQs

The usable volume of the PGO can be from 1 to 20 litres depending on the customer's needs

The PGO sampler is designed for sampling under pressure up to 35 MPa

Yes, we offer a 1 year warranty on the PGO sampler.

To order equipment and consult with our experts, you can contact us by phone, email or fill out the feedback form on our website. Our team will be happy to help you find a solution optimised for your needs.