Business Hours (UTC+3)

Mon-Fri: 8 AM - 5 PM

Mon-Fri: 8 AM - 5 PM

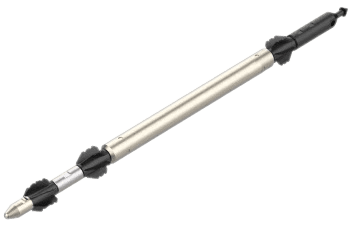

Spear-type scrapers SP-Tekhno

Designed for punching an asphaltene, resin, and paraffin plugs in an obstructed tubing string, are slickline or wireline conveyed scrapers

By clicking on the button, you consent to the processing of your personal data in accordance with the privacy policy

01

02

Direct equipment manufacturer

We guarantee the quality of our products

Certified equipment

Development according to drawings

Warranty service

Worldwide delivery

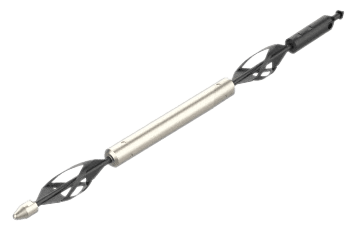

Spear-type scrapers “SP-Tekhno” are designed for initial punching an asphaltene, resin, and paraffin plugs in an obstructed tubing string.

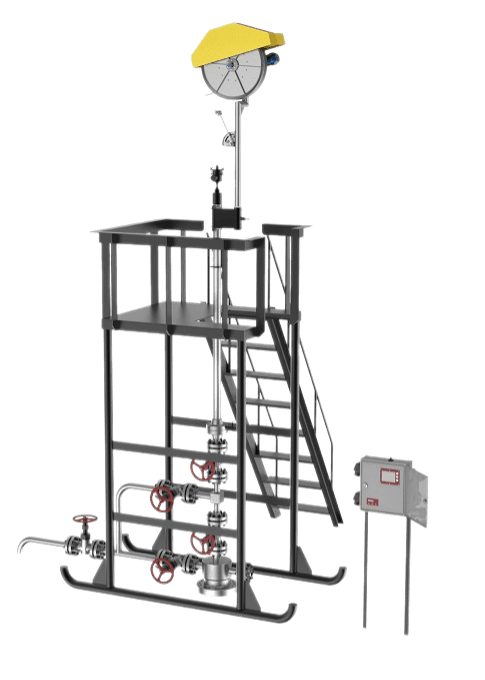

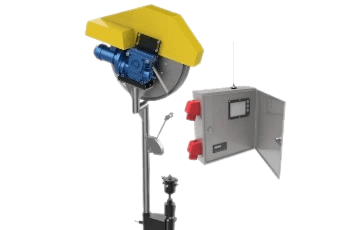

Effective cleaning is achieved through regularity of tubing cleaning using automatic well dewaxing unit “UDS-Tekhno 101” or semiautomatic slickline winch “LKI-Tekhno”.

Scrapers made by LLC NPF “TehSmart” have similar design as other scrapers such as dynamic scraper “SD”, expandable scraper, Bolotov’s scraper, PUR.55, TU.55, PU.55, DI.55, KI.55, PA.55, KP.55, PL.55, SR-73, SL-73, Stroev's scraper.

Scrapers by LLC NPF “TehSmart” are suitable for use with well dewaxing units of the following types: UDS, UDS-Tekhno, UDS-3000T, UDS-1M, UOK-NKT, PADUS, PADU-3M, DSA-18, MDS-010, Suleymanov’s winch.

To ensure effective wax removal, wellbore and fluid condition should be considered when selecting scraper elements for a cleaning job. Cutting ends are replaceable elements, and can be changed upon prior agreement with Client. Diameter of cutters, weights size and mass, scraper configuration can be agreed on prior to a cleaning job. Lead weight while preserving smaller size provides for larger mass for a more effective operation result.

A mandatory element is a swivel joint in order to prevent twisting of wire followed by kinks formation resulting in a potential job failure on a wellsite.

Effective cleaning is achieved through regularity of tubing cleaning using automatic well dewaxing unit “UDS-Tekhno 101” or semiautomatic slickline winch “LKI-Tekhno”.

Scrapers made by LLC NPF “TehSmart” have similar design as other scrapers such as dynamic scraper “SD”, expandable scraper, Bolotov’s scraper, PUR.55, TU.55, PU.55, DI.55, KI.55, PA.55, KP.55, PL.55, SR-73, SL-73, Stroev's scraper.

Scrapers by LLC NPF “TehSmart” are suitable for use with well dewaxing units of the following types: UDS, UDS-Tekhno, UDS-3000T, UDS-1M, UOK-NKT, PADUS, PADU-3M, DSA-18, MDS-010, Suleymanov’s winch.

To ensure effective wax removal, wellbore and fluid condition should be considered when selecting scraper elements for a cleaning job. Cutting ends are replaceable elements, and can be changed upon prior agreement with Client. Diameter of cutters, weights size and mass, scraper configuration can be agreed on prior to a cleaning job. Lead weight while preserving smaller size provides for larger mass for a more effective operation result.

A mandatory element is a swivel joint in order to prevent twisting of wire followed by kinks formation resulting in a potential job failure on a wellsite.

Components of SP-Tekhno

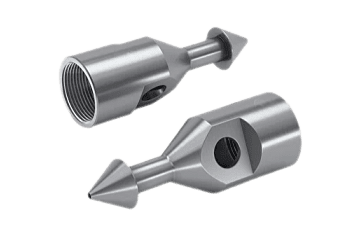

Punching Head

A punching head is a troubleshooting tool. Edges of the blades set at different angles and distances reduce cutting resistance facilitating effective removal of an asphaltene, resin, and paraffin plug.

Among advantages of blades made by OOO NPF “Tehsmart” are a rightly selected high strength steel and a qualitative sharpening of the blades.When selecting cutting heads it is recommended to use the heaviest and – at the same time – the narrowest weight stem. Its size should not exceed the size of the head.

Among advantages of blades made by OOO NPF “Tehsmart” are a rightly selected high strength steel and a qualitative sharpening of the blades.When selecting cutting heads it is recommended to use the heaviest and – at the same time – the narrowest weight stem. Its size should not exceed the size of the head.

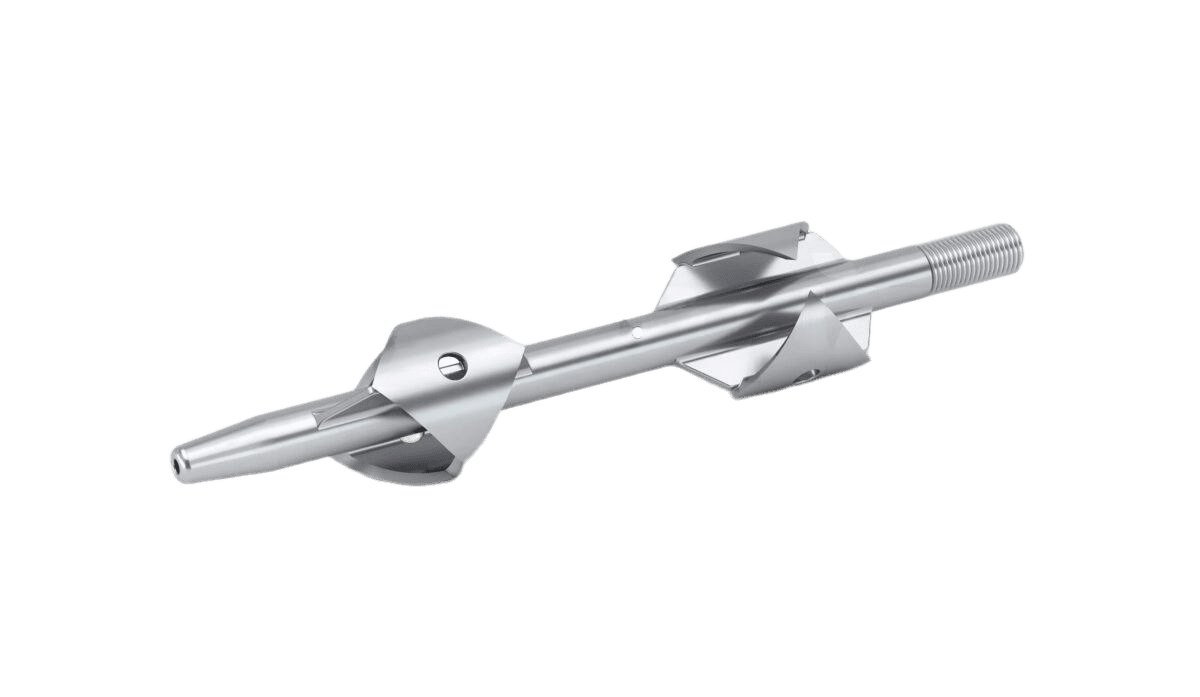

Weight Stem

Weight stems are made in two types: steel and lead

Lead weights/stems as compared to steel weights have larger mass and smaller size. This improves cleaning job quality and speed of preparatory operations.

Application of lead weights eliminates need in large multi-section lubricators.

Blades and cutters are securely fixed in the weight stem body with an Allen key screw.

Lead weights/stems as compared to steel weights have larger mass and smaller size. This improves cleaning job quality and speed of preparatory operations.

Application of lead weights eliminates need in large multi-section lubricators.

Blades and cutters are securely fixed in the weight stem body with an Allen key screw.

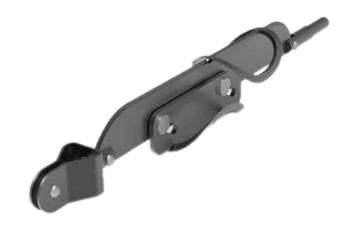

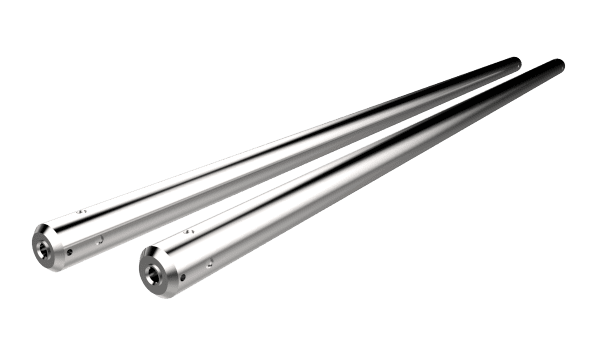

Swivel Joint

Swivel joint allows preventing twisting of the wire and formation of kinks

Is a highly effective failure prevention tool for dewaxing, wireline/ slickline and well testing operations.

Connection thread: male M27х1.5 / female M12х1.75 (other thread types can be made if requested by Client)

Is a highly effective failure prevention tool for dewaxing, wireline/ slickline and well testing operations.

Connection thread: male M27х1.5 / female M12х1.75 (other thread types can be made if requested by Client)

Rope Socket

Rope socket is designed for connecting 2.5 mm diameter wire and downhole tools.

Rope socket has a unified design among many manufacturers and remains universal. A special “mushroom-type” head, 20 mm OD, allows using the rope socket with head catcher “LU” or collet-type catcher “LTs” which prevents and promptly addresses failures caused by a wire breakdown.

Mandatory heat treatment ensures high tensile strength properties of the rope socket.

Connection thread: M27х1.5

Rope socket has a unified design among many manufacturers and remains universal. A special “mushroom-type” head, 20 mm OD, allows using the rope socket with head catcher “LU” or collet-type catcher “LTs” which prevents and promptly addresses failures caused by a wire breakdown.

Mandatory heat treatment ensures high tensile strength properties of the rope socket.

Connection thread: M27х1.5

Methods of ARPD removal - comparative characterisation

Work order

- 1The pigging tool is attached to the rope or cable via a ropsocket as part of a hoist-lowering mechanism (winch). With its own weight, the pig descends inside the oil and gas pipeline string to a depth greater than the cleaning area.

- 2When the scraper reaches the desired depth, a mechanism (winch, UDS) is switched on for lifting. The scraper rises higher and the deposits remain in place, avoiding obstructions during the cleaning process.

- 3Oil column flushing is carried out either in parallel with the cleaning process or at the end of the cleaning process. Different scraper diameters are used until the desired effect (increased oil flow rate) is achieved.

Technical characteristics of milling scrapers

Well dewaxing equipment

FAQs

The warranty period for SP-Techno scrapers is 12 months from the date of sale.

Spear-type Scrapers “SP-Tekhno” are designed for cleaning 60/73/89 mm tubing.

To order equipment and consult with our experts, you can contact us by phone, email or fill out the feedback form on our website. Our team will be happy to help you find a solution optimised for your needs.