Business Hours (UTC+3)

Mon-Fri: 8 AM - 5 PM

Mon-Fri: 8 AM - 5 PM

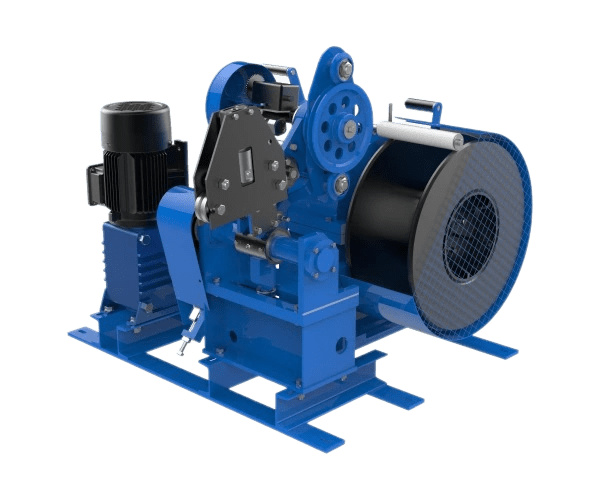

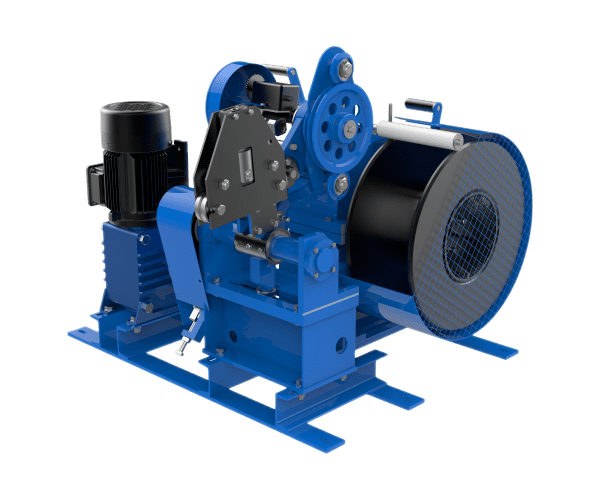

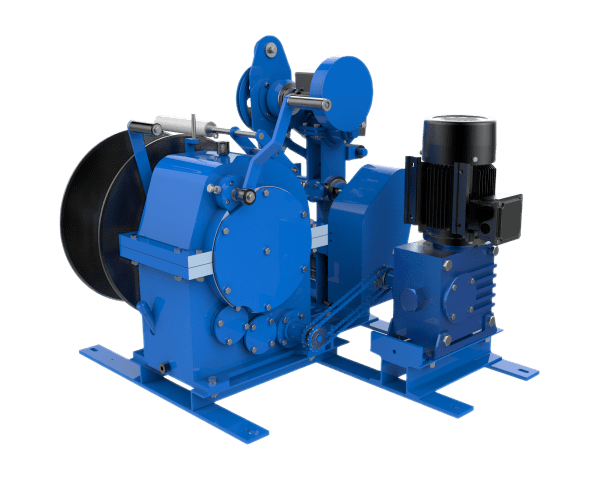

“LKI-TECHNO” slickline winch electric drive

For slickline conveyed logging and scraping of oil and gas wells with electric drive

By clicking on the button, you consent to the processing of your personal data in accordance with the privacy policy

01

02

Direct equipment manufacturer

We guarantee the quality of our products

Certified equipment

Development according to drawings

Warranty service

Worldwide delivery

“LKI-Techno” logging winch is used for running in memory tools, downhole samplers and paraffin scrapers and pulling them out of a well to the depth of up to 7000 m as part of dewaxing operations.

The winch features a clutch (friction disk) which allows you to avoid breaking in case of exceeding the wire tensile strength limit during trip to surface. The clutch discs are smoothly engaged under control by an operator when at work. The clutch also provides a “free run” of the tool under its own weight when the drive is unlocked. To slow down the drum during a free run, a pad-type handbrake is used. Parking brake represents a ratchet mechanism that fixes the run tool string at the required depth. For safe operation and to avoid hitting of the pulled tool against stuffing box, the tool is pulled to surface by means of a manual drive.

Automatic wire spooler with a measuring roller is part of the winch, and allows you to evenly lay wire under tension around the drum LKI-Techno is equipped with a mechanical speed counter SO-35 to track the depth of running a tool.

Upon Client’s request a Logging Control System “CKK-Techno 305” for monitoring acquisition of parameters of tripping operations followed by subsequent analysis on a computer or smartphone.

The winch features a clutch (friction disk) which allows you to avoid breaking in case of exceeding the wire tensile strength limit during trip to surface. The clutch discs are smoothly engaged under control by an operator when at work. The clutch also provides a “free run” of the tool under its own weight when the drive is unlocked. To slow down the drum during a free run, a pad-type handbrake is used. Parking brake represents a ratchet mechanism that fixes the run tool string at the required depth. For safe operation and to avoid hitting of the pulled tool against stuffing box, the tool is pulled to surface by means of a manual drive.

Automatic wire spooler with a measuring roller is part of the winch, and allows you to evenly lay wire under tension around the drum LKI-Techno is equipped with a mechanical speed counter SO-35 to track the depth of running a tool.

Upon Client’s request a Logging Control System “CKK-Techno 305” for monitoring acquisition of parameters of tripping operations followed by subsequent analysis on a computer or smartphone.

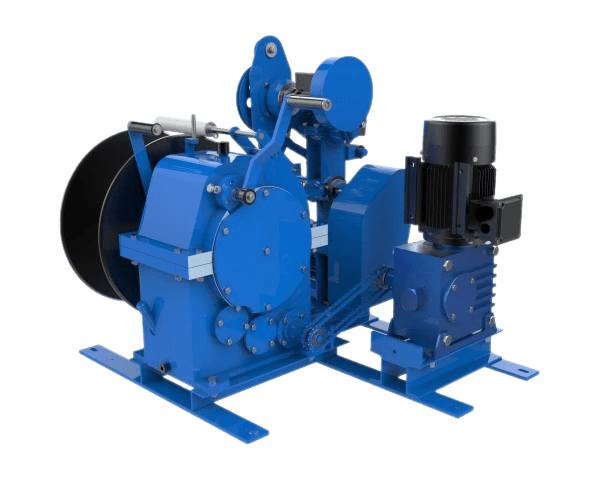

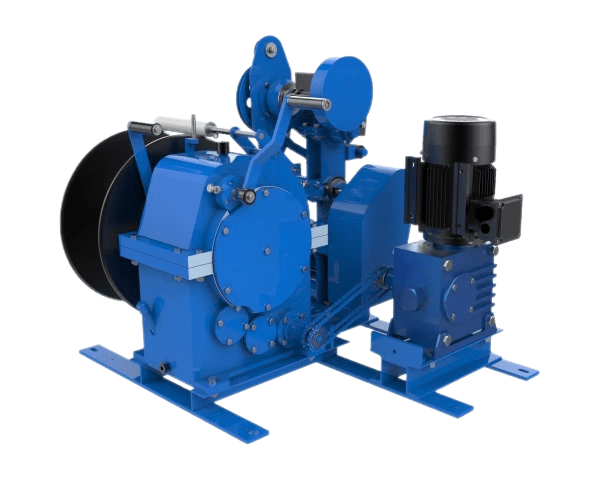

Slickline winch drive options

For slickline conveyed logging and scraping of oil and gas wells with electric drive

Electric drive

For slickline conveyed logging and scraping in oil and gas wells with mechanical drive from truck pto (power takeoff)

For slickline conveyed logging and scraping of oil and gas wells with an option of alternating use of electric and mechanical drive

A set of removable drums with wire allows you measuring pressure with downhole gauges simultaneously in several wells. Operator runs a tool into a well and wheels the drum out of the logging truck leaving it on a wellsite.

Controlled tool retrieval process reduces the chance of breaking wire (slickline). As an operator can reduce the torque transmitted to the output shaft of the winch using a clutch.

Parallel slickline operations

Failure risk reduction

Features

The clutch (clutch) in the winch gearbox allows you running tools and scrapers into wells under its own weight. This helps saving diesel of a standalone electric generator on flowing wellstock with no access to the 220V/380V power system.

High accuracy of measuring depth and speed of the wire movement is achieved due to no wire slipping on the measuring roller.

Running in well without starting the winch drive

Accurate depth and speed measurement

Technical Specifications

Pulling speed

| Drive type | Speed |

| Mechanical drive | up to 10 000 m/h |

| Gearmotor 2.2 / 4.0 kW, 1 500 rpm | up to 2 500 m/h |

| Gearmotor 2.2 / 4.0 kW, 3 000 rpm | up to 5 500 m/h |

| Gearmotor 2.2 / 4.0 kW, 3 000 rpm | up to 10 000 m/h |

Standard kit

LKI-Tekhno research winch with electric drive.

- Winch gearbox with a friction disc

- Automatic/mechanical wire spooler

- Mechanical speed/revolution counter SO-35

- Drums for scraper wire

- Gear motor (electric motor)

- Controls behind separation wall (as agreed with Client)

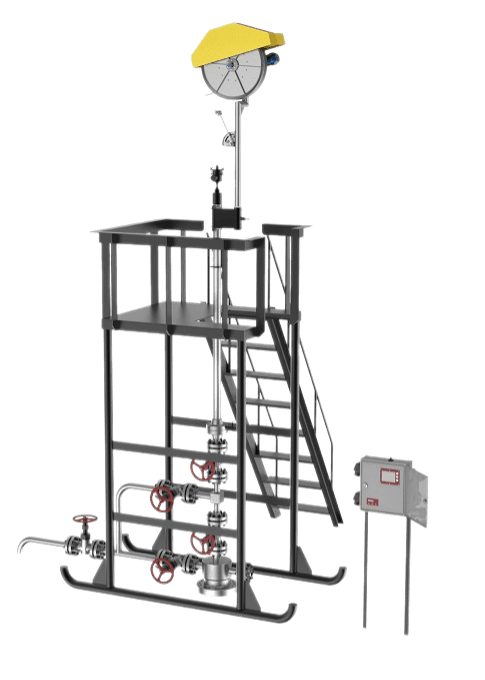

Well dewaxing equipment

Photo Gallery

FAQs

LKI-Techno winches are manufactured with electric, mechanical and combined drives.

LKI-Techno with electric drive are designed for borehole testing up to 7000 metres deep

The electrically driven LKI-Techno uses an automatic or mechanical wire stacker

Yes, we offer a 1 year warranty on electrically driven LKI-Techno.

To order equipment and consult with our experts, you can contact us by phone, email or fill out the feedback form on our website. Our team will be happy to help you find a solution optimised for your needs.