Business Hours (UTC+3)

Mon-Fri: 8 AM - 5 PM

Mon-Fri: 8 AM - 5 PM

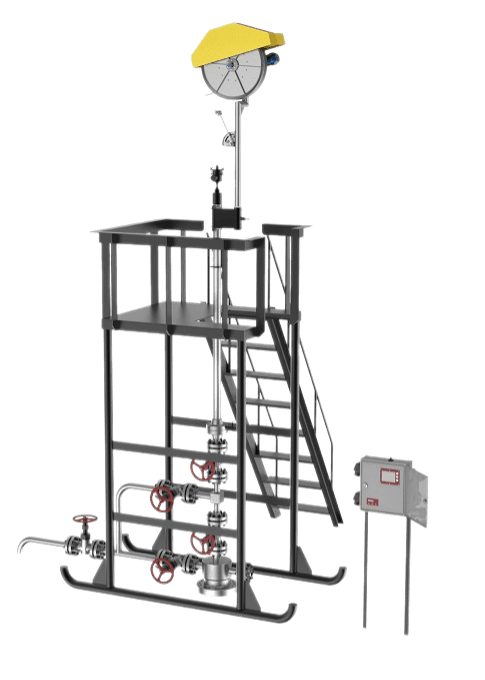

Wax cutter

Designed for wells dewaxing and removal of asphaltene, resin, and paraffin deposits using mechanical methods - scraping. Used in combination with a weight stem.

By clicking on the button, you consent to the processing of your personal data in accordance with the privacy policy

01

02

Direct equipment manufacturer

We guarantee the quality of our products

Certified equipment

Development according to drawings

Warranty service

Worldwide delivery

The paraffin cutter scraper is a multifunctional equipment for cleaning tubing-60, 73, 89 strings from asphalt-resin-paraffin deposits (ARPD) during oil production by both electric submersible pumps and gushing method.

The unique scraper has a reinforced blade that maintains a constant cross-section during movement and cuts the ARPD layer into four equal parts diametrically opposed. Subsequent division of the parts once again in half is carried out by carrier plates. The process of dewaxing of the tubing is carried out as a result of the downward descent of the pig. Due to the accumulated kinetic energy of the pig, ARPD is sheared off and broken down for effective cleaning.

The unique scraper has a reinforced blade that maintains a constant cross-section during movement and cuts the ARPD layer into four equal parts diametrically opposed. Subsequent division of the parts once again in half is carried out by carrier plates. The process of dewaxing of the tubing is carried out as a result of the downward descent of the pig. Due to the accumulated kinetic energy of the pig, ARPD is sheared off and broken down for effective cleaning.

Methods of ARPD removal - comparative characterisation

Features

- 1With its dual action, the scraper cuts through deposits in both upward and downward movements, sometimes reducing the number of up-and-down movements.

- 2Due to the special geometry and sharpening of the knives, the contact area with ARPD is minimised, which significantly reduces the effort required to remove paraffin deposits.

- 3Suitable for use with: UDS-1, UDS-Techno, MDSA dewaxing mechanism, PADUS-M, Suleymanov winch, LIS-1 winch.

- 4Designed for cleaning steel tubing. Note: avoid using the wax cutter on coated tubing.

Technical characteristics of the scrapers

Well dewaxing equipment

FAQs

The warranty period for our wax cutters is 12 months from the date of sale.

Paraffin cutters are designed for cleaning 60/73/89 mm tubing.

To order equipment and consult with our experts, you can contact us by phone, email or fill out the feedback form on our website. Our team will be happy to help you find a solution optimised for your needs.