Business Hours (UTC+3)

Mon-Fri: 8 AM - 5 PM

Mon-Fri: 8 AM - 5 PM

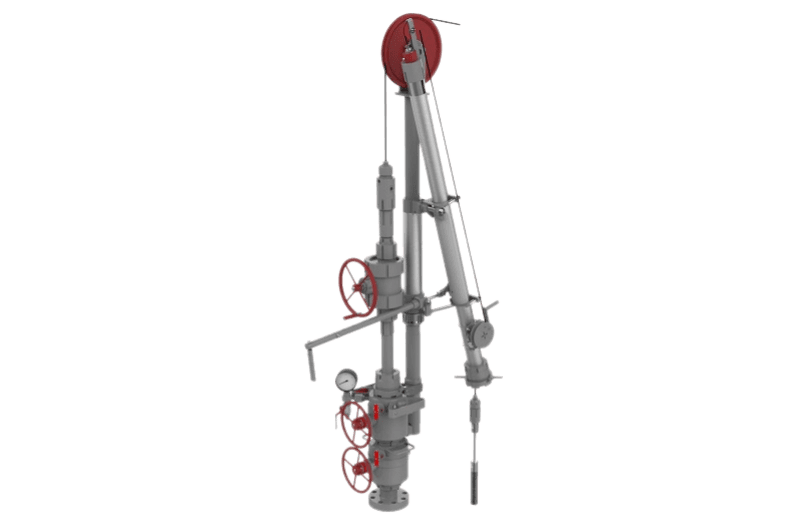

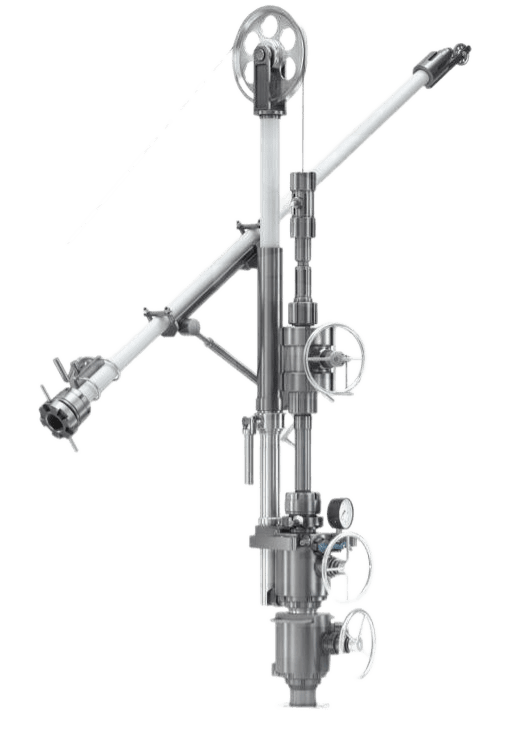

ULGIS-TEKHNO – a lubricator unit

For sealing off wellhead pressure by method of pressure locking while running tools in and out of a well on a wireline

By clicking on the button, you consent to the processing of your personal data in accordance with the privacy policy

01

02

Direct equipment manufacturer

We guarantee the quality of our products

Certified equipment

Development according to drawings

Warranty service

Worldwide delivery

ULGIS – Tekhno is designed for running (retrieving) downhole logging tools into a well with wellhead pressure of up to 35MPa. It allows running in sections downhole equipment while keeping a well pressurized by efforts of two individuals without involving any special rig-up/lifting equipment (a mast, a rig, a crane). The unit design enables performing operations on flowing oil and gas and injection wells with a rigged up X-mas tree as well as on the wells where pressure may increase at the wellhead as a result of wireline logging operations or for other reasons. Application of ULGIS-Tekhno allows generating reliable well data because flowing and injection regimes remain unaffected.

Due to modular design the unit can be made up “rig-free” – manually within 60 minutes. The modular structure ensures an easy installation right on the top of wellhead equipment with maximum weight of each module less than 40 kg. The unit installation point should be 1650 mm above the top flange of the X-mas tree to allow an easy access to all of the wellhead equipment elements.

A tool string is made up with lead filled stems and a special head positioned above the tool to seal off a live well at the wellhead in a BOP section (by latching on a neck of the stem head) prior to connecting a logging tool to a cable head or other element.

A pressure locking chamber made of aluminium alloy with a manual winch and a wire stuffing box set in a lifting and rotating pulley block of the working platform allows running equipment of any length and using as many weight stems in the run string as needed to offset well pressure.

Logging tools and stems enter a pressure lock chamber driven by a manual winch and a steel wire guided through the lifting and rotating pulley block. Once the tool is in the pressure lock tube, other string elements can be made up into the tool string and run it into a well.

Due to modular design the unit can be made up “rig-free” – manually within 60 minutes. The modular structure ensures an easy installation right on the top of wellhead equipment with maximum weight of each module less than 40 kg. The unit installation point should be 1650 mm above the top flange of the X-mas tree to allow an easy access to all of the wellhead equipment elements.

A tool string is made up with lead filled stems and a special head positioned above the tool to seal off a live well at the wellhead in a BOP section (by latching on a neck of the stem head) prior to connecting a logging tool to a cable head or other element.

A pressure locking chamber made of aluminium alloy with a manual winch and a wire stuffing box set in a lifting and rotating pulley block of the working platform allows running equipment of any length and using as many weight stems in the run string as needed to offset well pressure.

Logging tools and stems enter a pressure lock chamber driven by a manual winch and a steel wire guided through the lifting and rotating pulley block. Once the tool is in the pressure lock tube, other string elements can be made up into the tool string and run it into a well.

Configuration & Assembly Elements

Technical features

- 1Breakdown of the installation into several individual units, which can be easily assembled into a single structure directly on the fountain fitting (maximum weight of each unit is no more than 42 kg).

- 2The use of lead weights placed over the device ensures wellhead tightness in the preventer unit (by clamping the rod of the weight before the device is connected to the cable lug) and allows the required number of weights to be dialed in depending on the wellhead pressure.

- 3The cable handling mechanism prevents damage to the outer layer of the cable, with a pulling force of up to 60kg, equivalent to the weight of four weights. This reduces the number of sluicing operations and minimises gland leakage, even to the point of eliminating it altogether.

- 4Use of a temporary (sluice) column made of aluminium alloy D-16 with a hand winch and a wire gland fixed in a lift-and-turn mechanism on the column.

- 5Installing a sealing assembly (gland) of wire or cable at the wellhead and connecting it to a geophysical tool already pressurised in the borehole.

- 6Placing the ‘top’ logging unit (roller) on a rack securely mounted on the preventer unit using the concepts described above.

FAQs

ULGIS-Techno is designed for working pressure up to 35 MPa.

Yes, we give a 1 year warranty on the ULGIS-Techno lubricator unit.

To order equipment and consult with our experts, you can contact us by phone, email or fill out the feedback form on our website. Our team will be happy to help you find a solution optimised for your needs.