Business Hours (UTC+3)

Mon-Fri: 8 AM - 5 PM

Mon-Fri: 8 AM - 5 PM

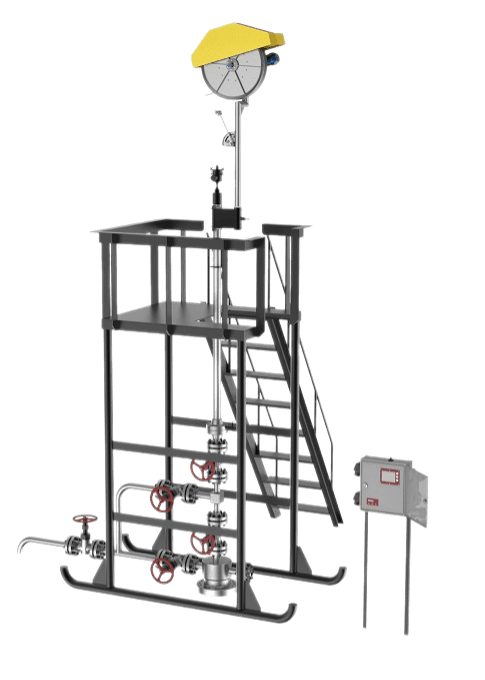

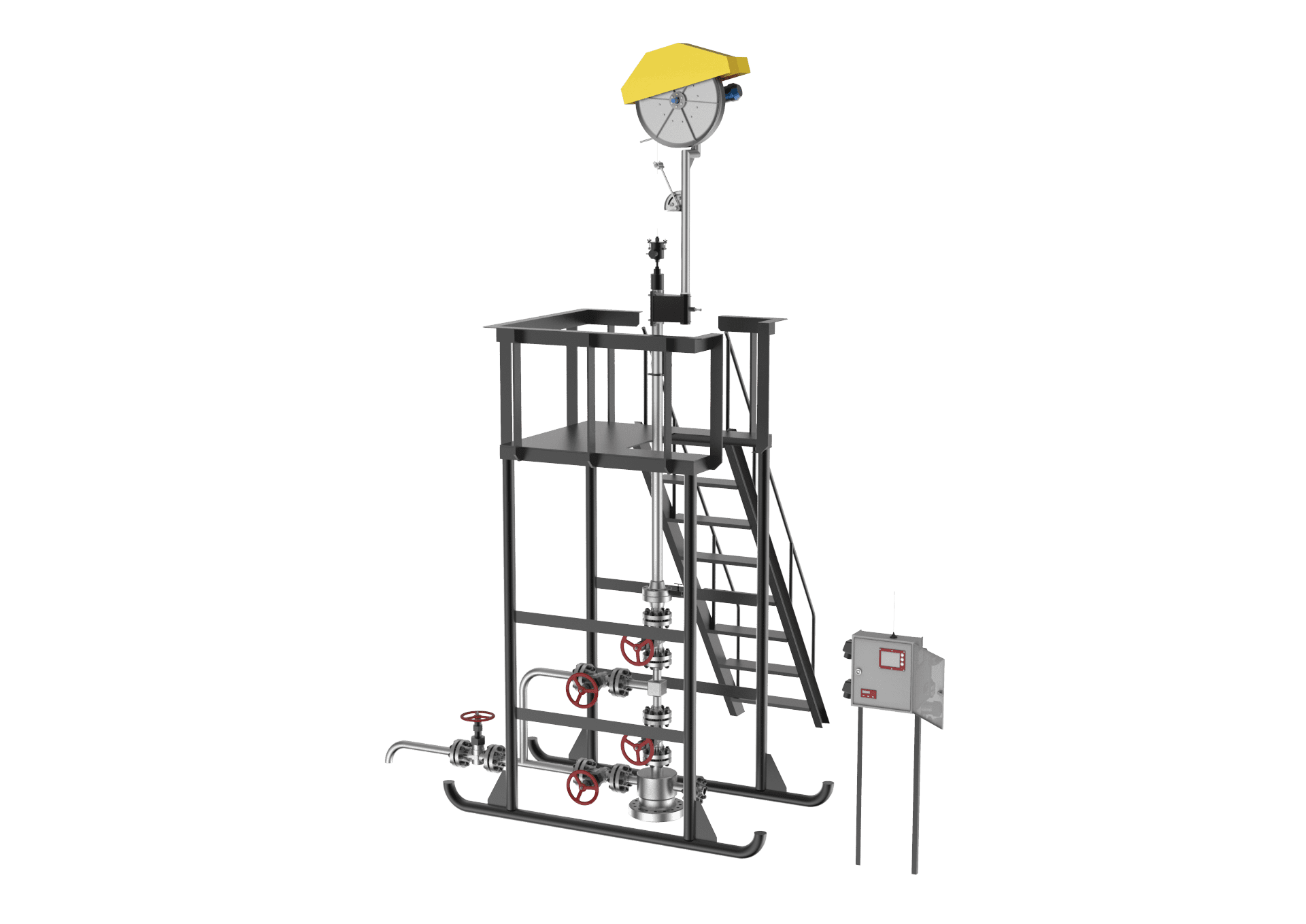

Well Dewaxing Unit

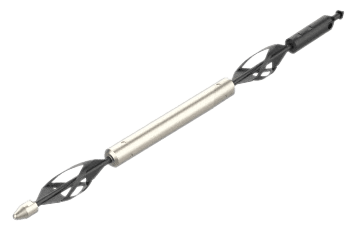

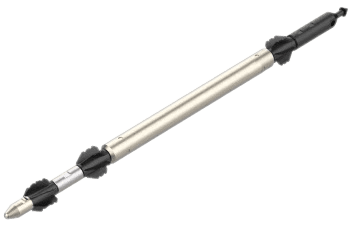

UDS-TEKHNO dewaxing unit is designed for fully automated mechanical cleaning of tubing internal surface using a scraper from asphaltene, resin, and paraffin deposited in ESP operated and flowing wells.

By clicking on the button, you consent to the processing of your personal data in accordance with the privacy policy

01

02

Direct equipment manufacturer

We guarantee the quality of our products

Certified equipment

Development according to drawings

Warranty service

Worldwide delivery

The unit has an automatic, semiautomatic and manual cleaning modes:

- in automatic mode the whole cleaning process is managed by a control unit

- in semiautomatic mode an operator manages running in, stopping, and pulling scraper out of the well using a control unit

- in manual mode an operator pulls out and runs a scraper in the well using a manually driven handle

- UDS can be monitored using an online service that includes:

-Remote control over a cleaning process

-View of unit performance archive

- Can be connected to a Client’s remote control system through protocol ModBus RTU, port Rs485

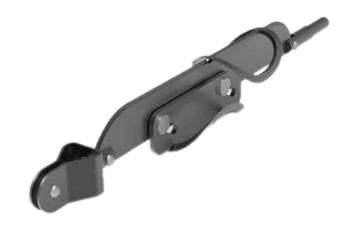

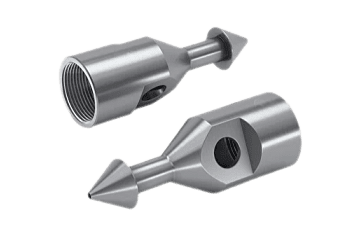

- Wellhead catcher protects a scraper from cutting a slickline wire in the lubricator

- Synchronizing UDS with ESP

CLEANING MODES

FEATURES

OPERATION PRINCIPLES

1

When starting for the first time in an automatic mode scraper is pulled to surface and is sensed with scraper upper position sensor “DVPS” when entering a wellhead lubricator

3

Whilst cleaning, wire tension sensors:

- Prevent slacking off/unwinding of slickline

- Protect a slickline from breaking while pulling to surface

2

When the scraper reaches a wellhead the unit starts a cleaning cycle: it runs the scraper in to the desired depth, and, then, pulls it to surface cleaning the targeted interval. Whilst running in/pulling out a mill (a blade) of the scraper cuts asphaltene, resin, and paraffin deposits from internal walls of the tubing

4

After cleaning scraper is lowered to a parking point, or remains in the heated lubricator

5

Next cleaning phases are started automatically as per Client’s schedule captured in the unit settings

CLEANING PARAMETERS

- Cleaning interval (measured depth)

- Scraper movement speed

- Drive overload protection to avoid overload and emergency situations

- Depth of scraper parking whilst waiting on the next cleaning job

- Cleaning duration: how frequently cleaning mode is activated – a range from every 6 hours to once per week

- Unit performance when passing complicated intervals: number of independent attempts to get through an obstacle and a pause between the attempts needed for a scraper to displace paraffin with its own weight

- Additional functions can be added if needed

Features of UDS-Tekhno

- Attractive way to control a UDS station via GSM cellular network!

- Do you want to be able to operate in automatic or semi-automatic mode according to set parameters? We offer a solution - a station with remote control function. Set up the station operator and control the scraper operation as you wish - lower, raise or stop its movement.

- Thanks to a modem, the station transmits data to an online monitoring service, allowing you to monitor and control the operation of the UDS from anywhere via the Internet.

- Don't worry about overloads and emergencies - the plant has a drive load limit.

- Receive daily reports on station operation in convenient XLS/TXT/CSV formats, monitoring remotely from any Internet-connected device. Manage your UDS easily and conveniently with our solution!

Well dewaxing equipment

TECHNICAL SPECIFICATIONS

FAQs

The well dewaxing unit can be controlled via the control station or remotely via tehsmart.online.

UDS-Techno is manufactured in 220 V and 380 V versions.

Yes, on customer request we can produce a dewaxing unit in corrosion-resistant version K1, K2 or K3.

Yes, we give a 1 year warranty on the UDS-Techno well dewaxing unit.

To order equipment and consult with our experts, you can contact us by phone, email or fill out the feedback form on our website. Our team will be happy to help you find a solution optimised for your needs.