Business Hours (UTC+3)

Mon-Fri: 8 AM - 5 PM

Mon-Fri: 8 AM - 5 PM

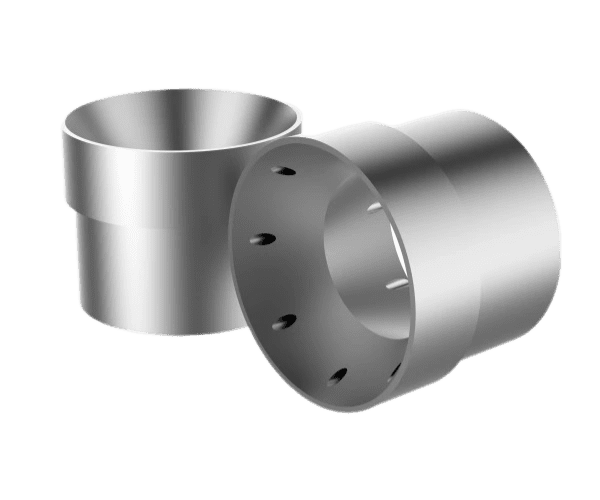

No-go ring

Designed to prevent a scraper or a tool from dropping down into bottomhole or causing damage to esp followed by a potential well depressurization/lost well integrity

By clicking on the button, you consent to the processing of your personal data in accordance with the privacy policy

01

02

Direct equipment manufacturer

We guarantee the quality of our products

Certified equipment

Development according to drawings

Warranty service

Worldwide delivery

The no-go ring “PPK” is installed in a union joint of tubing whilst running in a new string or performing workover operations on the well. The PPK ring is an oilfield equipment and is designed to protect downhole pumping equipment of oil producing wells from the fall (drop) of scraper devices used for dewaxing the tubing string from paraffin and ashphaltene deposits during a wire or cable conveyed tripping in and out of the well.

Technical Specifications

- The depth of the ring installation is selected depending on the depth of scraping and targeted depth intervals of well testing and logging jobs

- If bore hole of the ring exceeds the diameter of the run logging tools, then a well may be easily logged to intervals deeper than the no-go ring set point

- In most cases, it is recommended to install the ring on the tubing pipe at an estimated depth of about 1000 m from the wellhead

- A deeper installation of the ring is not recommended, because on the winch drum during fishing operations, there may not be enough wire length to run the collet catcher, as well as due to the difficulty of engaging a fish/lost tool at a greater depth

Operating Principle

Photo Gallery

FAQs

The PPK-Techno anti-flight ring is manufactured with bore diameters of 36, 38, 40 and 42 mm.

The anti-flight ring is applicable to 60, 73 and 89 mm tubing strings.

Yes, we offer a 1 year warranty on the PPK-Techno anti-flight ring.

To order equipment and consult with our experts, you can contact us by phone, email or fill out the feedback form on our website. Our team will be happy to help you find a solution optimised for your needs.