Business Hours (UTC+3)

Mon-Fri: 8 AM - 5 PM

Mon-Fri: 8 AM - 5 PM

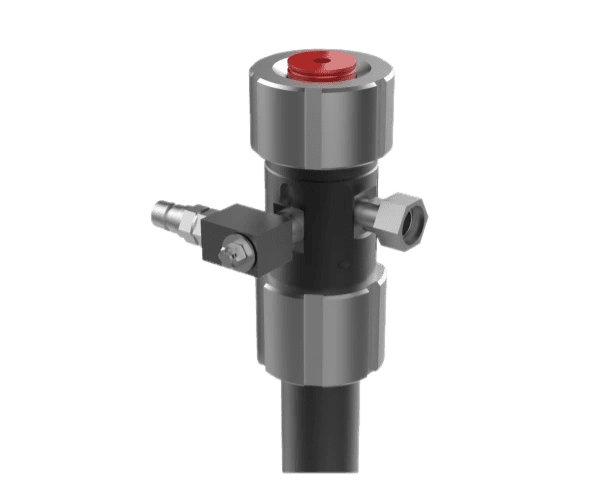

Hydraulic stuffing box

For sealing lubricator at the wellheads of oil and injection well, for cleaning slickline or wireline cable from well fluid.

By clicking on the button, you consent to the processing of your personal data in accordance with the privacy policy

01

02

Direct equipment manufacturer

We guarantee the quality of our products

Certified equipment

Development according to drawings

Warranty service

Worldwide delivery

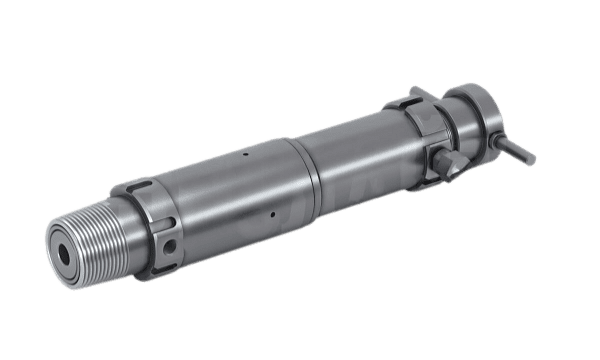

A hydraulically operated cable sealing device (analogous to wellhead packoff devices ZUG-4, ZUG -4M, ZUG -6, UGG-35, UGL-35) is used for sealing cable or wire whilst conducting well logging or well testing operations. It is installed as part of a wellhead lubricator whilst using a technology of entering a well under pressure.

Hydraulic stuffing box is operated in combination with an oil pump. An exerted pressure allows creating a seal by compressing seal elements around the wireline or slickline. Hydraulic stuffing box also has a mud/well fluid bleedoff sub to ensure the outstanding well fluid is removed from the stuffing box body.

Design: options with labyrinth and packed gland seal, for gas condensate and oil wells accordingly.

Service life – 5 years from commissioning.

UGG-35 is designed for application in the temperate climate as per GOST 16350-80.

Application zone of UGG-35 while operation – 1 as per GOST 15150-69

Hydraulic stuffing box is operated in combination with an oil pump. An exerted pressure allows creating a seal by compressing seal elements around the wireline or slickline. Hydraulic stuffing box also has a mud/well fluid bleedoff sub to ensure the outstanding well fluid is removed from the stuffing box body.

Design: options with labyrinth and packed gland seal, for gas condensate and oil wells accordingly.

Service life – 5 years from commissioning.

UGG-35 is designed for application in the temperate climate as per GOST 16350-80.

Application zone of UGG-35 while operation – 1 as per GOST 15150-69

After the wellhead equipment is installed on the well, apply LPG to the upper chamber, having previously cleaned and inspected the threaded parts. Place the oil station on a flat pad at the desired distance from the wellhead, opening the vent tank plug. Connect the high-pressure hose to the LPG and the oil station with the help of the hose coupler, ensuring that it is filled with oil. Attach the discharge hose to the LPG discharge connection and depressurise the system. Equalise the pressure in the sluice with the well, open the fuse preventer and start work. While performing the tasks, control tightness and cable tension by adjusting pressure in the hydraulic system - increasing it by turning the MSR-2 pump knob or decreasing it by opening the pressure relief knob.

Principle of operation

Technical specifications

Photo Gallery

FAQs

Maximum cable pulling force - 70 kN

Hydraulic gland packing is designed for operation under pressure up to 35 MPa

Yes, we give a 1 year warranty on the hydraulic packing unit.

To order equipment and consult with our experts, you can contact us by phone, email or fill out the feedback form on our website. Our team will be happy to help you find a solution optimised for your needs.