Business Hours (UTC+3)

Mon-Fri: 8 AM - 5 PM

Mon-Fri: 8 AM - 5 PM

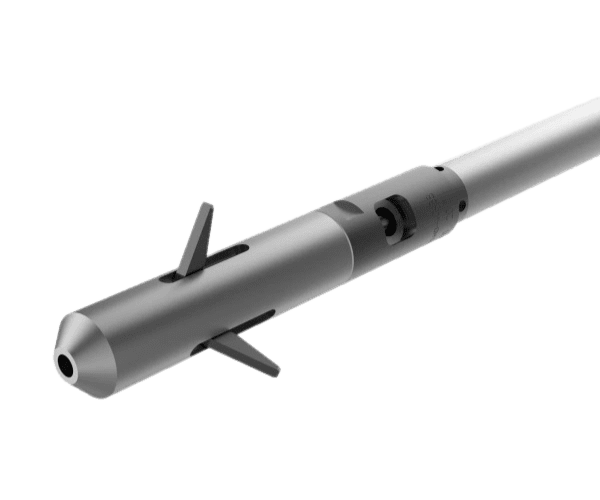

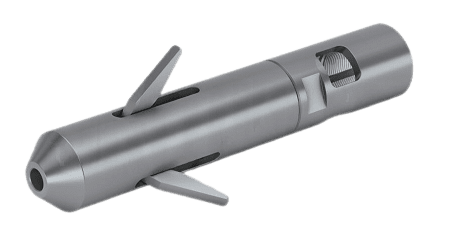

Downhole flow-through sampler “PGP-Techno"

Designed for the selection, storage and transportation of reservoir fluid

By clicking on the button, you consent to the processing of your personal data in accordance with the privacy policy

01

02

Direct equipment manufacturer

We guarantee the quality of our products

Certified equipment

Development according to drawings

Warranty service

Worldwide delivery

The downhole flow-through sampler “PGP-Techno" is used for taking downhole samples of reservoir fluid in production and exploration wells, as well as transporting it under pressure for further fluid testing.

- Sample volume - 540 cm3

- Reliable retention of the sample by valve mechanism

- Upgraded butt relay mechanism

- Slickline and wireline cable conveyance

Technical specifications

- Sampling chamber - 3 ea.

- Butt relay - 1 ea.

- Discharge head - 2 ea.

- Rope socket - 1 ea.

- Spare parts and tools - 1 set

- Passport, operating manual and pressure test certificate - 1 set

Standard kit

Stop descending when the device reaches the set depth.

Lower the activated sampler into the tubing string to the level where the sample will be collected.

1

Allow time for the oil that entered the device chamber during the run to be completely replaced by oil flowing into the well from the reservoir.

2

Work order

During the lifting of the sampler, the difference between the pressure inside the sampler and the external pressure increases, which causes the valves to fit tightly to their seats, thus guaranteeing the tightness of the collected sample.

After this period, begin pulling the sampler to the surface. During the lift, the discharge head arms will touch the nearest pipe coupling connection, which will activate the coupling relay and the arms will stow without interfering with the continued lifting of the instrument.

3

Lowering and raising the sampler in the borehole should be done at a speed not exceeding 30 m/min (0.5 m/s or 1800 m/h).

5

4

6

- The sampler layout includes a sampling chamber equipped with a two-valve locking mechanism and a butt relay

- For sampling, the sampler must be run to the required depth and then raised to the nearest tubing coupling

- When the butt relay is triggered, the sample is locked in the sampling chamber. The selected sample is transferred to the fluid testing equipment using two discharge heads

Operating Principle

Video operating procedure for “PGP-TEKHNO”

Photo Gallery

FAQs

The PGP-Techno depth sampler is designed for pressures up to 40 MPa.

The diameter of the sampler is 38mm.

Yes, we offer a 1-year warranty on the PGP-Techno flow-through depth sampler.

To order equipment and consult with our experts, you can contact us by phone, email or fill out the feedback form on our website. Our team will be happy to help you find a solution optimised for your needs.