Business Hours (UTC+3)

Mon-Fri: 8 AM - 5 PM

Mon-Fri: 8 AM - 5 PM

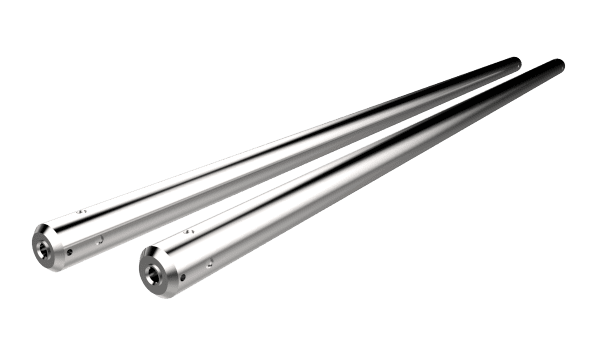

MILLING SCRAPERS SF-TEKHNO

FOR CLEANING TUBING IN HIGH RATE WELLS

By clicking on the button, you consent to the processing of your personal data in accordance with the privacy policy

01

02

Direct equipment manufacturer

We guarantee the quality of our products

Certified equipment

Development according to drawings

Warranty service

Worldwide delivery

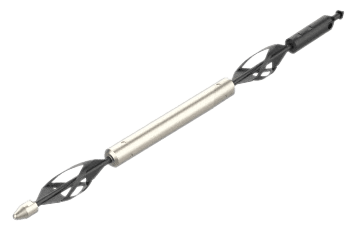

Cutter pigs from TehSmart are designed for removal of ARPD at high flow rate wells. The rotation of the cutting head at the required flow allows effective cleaning of the inner surface of the tubing from paraffin deposits.

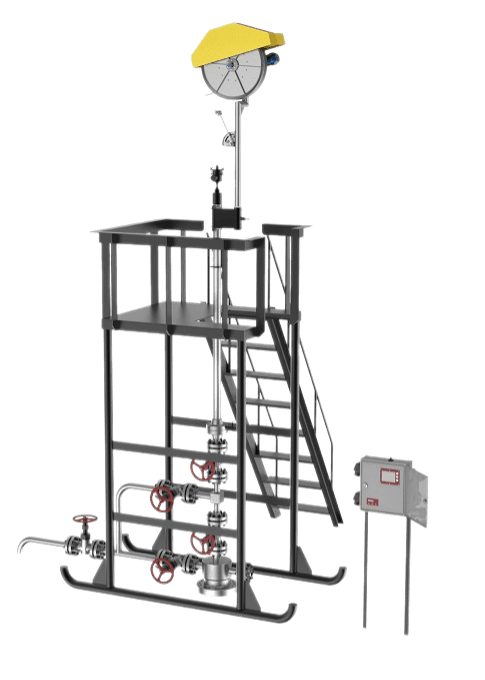

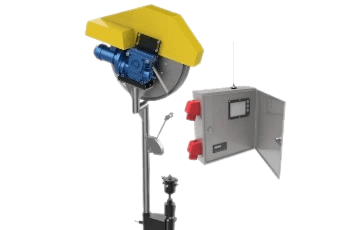

For effective tubing string cleaning it is important to perform cleaning on a regular basis using UDS-Tekhno 101 well dewaxing unit or LKI-Tekhno semi-automatic winches.

TehSmart scrapers are similar to dynamic and sliding scrapers, as well as to scrapers of other manufacturers. They can be used on different types of well dewaxing units.

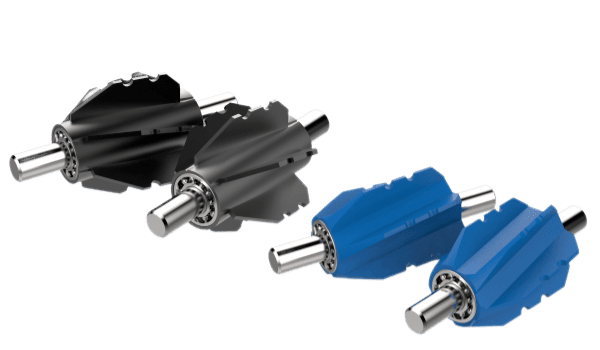

Depending on well requirements, the best pig configuration can be selected, including cutter head sizes, dimensions and weight of the weighting weight. The cutter heads are easily interchangeable to harmonise the set.

It is important to have a carabiner to prevent wire twist and possible downhole accidents.

To work in polymer-coated tubing, pigs are equipped with high-strength plastic cutters to protect the inner surface of the pipe from damage.

For effective tubing string cleaning it is important to perform cleaning on a regular basis using UDS-Tekhno 101 well dewaxing unit or LKI-Tekhno semi-automatic winches.

TehSmart scrapers are similar to dynamic and sliding scrapers, as well as to scrapers of other manufacturers. They can be used on different types of well dewaxing units.

Depending on well requirements, the best pig configuration can be selected, including cutter head sizes, dimensions and weight of the weighting weight. The cutter heads are easily interchangeable to harmonise the set.

It is important to have a carabiner to prevent wire twist and possible downhole accidents.

To work in polymer-coated tubing, pigs are equipped with high-strength plastic cutters to protect the inner surface of the pipe from damage.

Components of SF-Tekhno

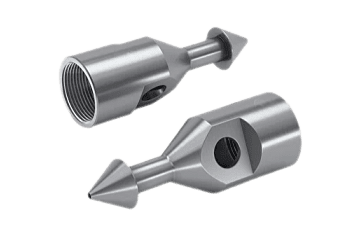

Cutterheads

Cutterheads are made in two types: steel and plastic of high strength innovative polymer. Plastic cutters do not create scratches on internal surface of polymer tubing.

The model design allows – at sufficient well rates – for high speed axial rotation of the cutter (mill). The most effective cleaning is achieved when using coupled cutters – each rotating in different directions (cutters are coupled with a special hub).

When selecting cutting heads it is recommended to check size of a sinker bar (weight stem). Its size should not exceed the size of the head.

The model design allows – at sufficient well rates – for high speed axial rotation of the cutter (mill). The most effective cleaning is achieved when using coupled cutters – each rotating in different directions (cutters are coupled with a special hub).

When selecting cutting heads it is recommended to check size of a sinker bar (weight stem). Its size should not exceed the size of the head.

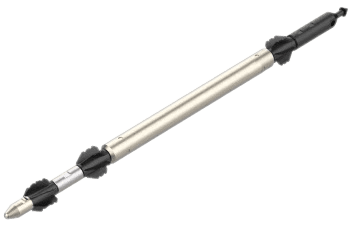

Weight Stem

Stems are made of steel or lead

Lead stems are more preferred than steel stems in order to maximize cleaning quality and speed of pre-job operations as lead weighs more than steel, thus, resulting in a smaller size of stem.

Application of lead weights eliminates need in large multi-section lubricators.

Blades and cutters are securely fixed in the weight stem body with an Allen key screw.

Lead stems are more preferred than steel stems in order to maximize cleaning quality and speed of pre-job operations as lead weighs more than steel, thus, resulting in a smaller size of stem.

Application of lead weights eliminates need in large multi-section lubricators.

Blades and cutters are securely fixed in the weight stem body with an Allen key screw.

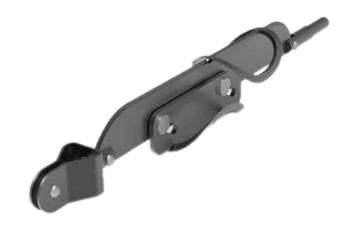

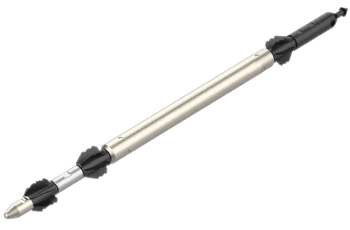

Swivel Joint

Swivel joint allows preventing twisting of the wire and formation of kinks

Is a highly effective failure prevention tool for dewaxing, wireline and slickline conveyed interventions.

Connection thread: male M27х1.5 / female M12х1.75 (other thread types can be made if requested by Client)

Is a highly effective failure prevention tool for dewaxing, wireline and slickline conveyed interventions.

Connection thread: male M27х1.5 / female M12х1.75 (other thread types can be made if requested by Client)

Rope Socket

Rope socket is designed for connecting 2.5 mm diameter wire and downhole tools.

Rope socket has a unified design among many manufacturers and remains universal. A special “mushroom-type” head, 20 mm OD, allows using the rope socket with head catcher “LU” or collet-type catcher “LTs” which prevents and promptly addresses failures caused by a wire breakdown.

Mandatory heat treatment ensures high tensile strength properties of the rope socket.

Connection thread: M27х1.5

Rope socket has a unified design among many manufacturers and remains universal. A special “mushroom-type” head, 20 mm OD, allows using the rope socket with head catcher “LU” or collet-type catcher “LTs” which prevents and promptly addresses failures caused by a wire breakdown.

Mandatory heat treatment ensures high tensile strength properties of the rope socket.

Connection thread: M27х1.5

Methods of ARPD removal - comparative characterisation

Work order

- 1The scraper is attached to the rope by means of a ropsocket (a special attachment unit, either in the form of a bell or a roller) within the hoisting and transport mechanism (in our case, a winch). Under the influence of its own weight, the scraper is lowered into the wellbore to a depth exceeding the cleaning level.

- 2When the scraper reaches the specified depth, the lifting device (winch) is activated and the scraper begins to rise, removing sediment from the surface (while milling) of the oil well casing. At the same time, the scraper rises higher, leaving the cleaning products in place without the possibility of plugging. The oil well casing is flushed either during or after the cleaning process.

Technical characteristics of milling scrapers

Well dewaxing equipment

Photo gallery of milling scrapers

FAQs

The warranty period for SF-Techno scrapers is 12 months from the date of sale.

SF-Techno cutter pigs are designed for cleaning 60/73/89 mm tubing.

To order equipment and consult with our experts, you can contact us by phone, email or fill out the feedback form on our website. Our team will be happy to help you find a solution optimised for your needs.