Business Hours (UTC+3)

Mon-Fri: 8 AM - 5 PM

Mon-Fri: 8 AM - 5 PM

Smarts of sliding

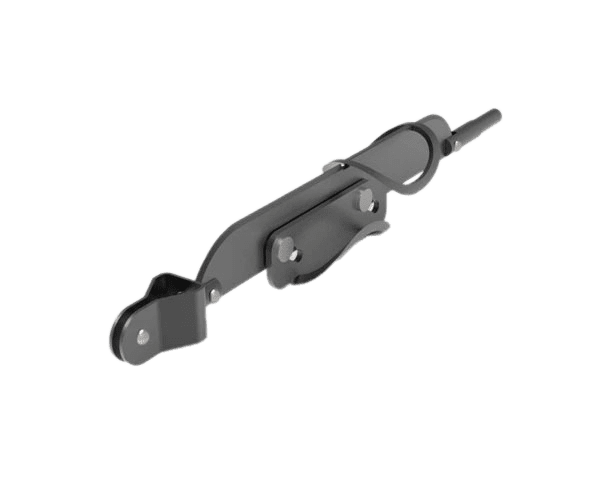

The scrapers of the sliding NKT60 and NKT73 are designed for deParafinization (cleaning the NCT column) from asphaltosmol paraffin deposits of APOs with medium and small morons, including in inclined wells with invadinometry up to 45 degrees from the vertical.

By clicking on the button, you consent to the processing of your personal data in accordance with the privacy policy

01

02

Direct equipment manufacturer

We guarantee the quality of our products

Certified equipment

Development according to drawings

Warranty service

Worldwide delivery

Legal scrapers of the production of NPF Tech Smart LLC are analogues of such scrains as a petal scraper, an “Usin” scraper, sliding scrapers of other manufacturers.

Scrapers of NPF LLC Techsmart are suitable for use on the installations of wells of wells of the following types: UDS, UDS, UDS-3000T, UDS-1M, UK-NNT, Padus, PADA-3M, DSA-18, MDS-010, MDS- 3000, MDS-4000, Suleimanova winch.

Depending on the condition and requirements of the well fund, you can choose the most optimal layout of the scraper for dearafinization. The scrains of the sliding NKT60 and NKT73 can be equipped with cargo with weighting with diameters of 28, 32, 36, 38, 42mm.

The weight of the scraper, depending on the cargo, is from 8.5 kg to 19 kg.

The overall length of the sliding scraper assembled with the load is from 1350 mm to 1650 mm

The cargo-hearing can be made in two types: steel or lead.

The lead cargo in comparison with a steel load has a large weight with a lower overall length, and therefore the need to use multi -section lubricators with a length of more than 2000 mm disappears.

A sliding scraper assembly with a load - a weighting agent drops into the well below the cleaning interval. At the same time, the knives fold, maximizing the diameter of the scraper and facilitating the descent. After passing the scraper down to the required depth, the detachment of the detonation begins the rise of the scraper. When lifting the knives, the scraping, clinging to paraffins, moves apart to the working position. The open knives, moving up the scraper, cleans the NCT.

The diameter of the knives in the working position is calculated taking into account the necessary clearance between the knives and the walls of the pipe. For NCT 73 - a diameter of knives 56 mm, for NCT 60 - a diameter of 44 mm. Thanks to this, jamming is excluded during cleaning, but at the same time, already during the first passage in most cases, the passing diameter of the TCT increases to the maximum possible working condition of the oil -containing fluid duct.

Scrapers of NPF LLC Techsmart are suitable for use on the installations of wells of wells of the following types: UDS, UDS, UDS-3000T, UDS-1M, UK-NNT, Padus, PADA-3M, DSA-18, MDS-010, MDS- 3000, MDS-4000, Suleimanova winch.

Depending on the condition and requirements of the well fund, you can choose the most optimal layout of the scraper for dearafinization. The scrains of the sliding NKT60 and NKT73 can be equipped with cargo with weighting with diameters of 28, 32, 36, 38, 42mm.

The weight of the scraper, depending on the cargo, is from 8.5 kg to 19 kg.

The overall length of the sliding scraper assembled with the load is from 1350 mm to 1650 mm

The cargo-hearing can be made in two types: steel or lead.

The lead cargo in comparison with a steel load has a large weight with a lower overall length, and therefore the need to use multi -section lubricators with a length of more than 2000 mm disappears.

A sliding scraper assembly with a load - a weighting agent drops into the well below the cleaning interval. At the same time, the knives fold, maximizing the diameter of the scraper and facilitating the descent. After passing the scraper down to the required depth, the detachment of the detonation begins the rise of the scraper. When lifting the knives, the scraping, clinging to paraffins, moves apart to the working position. The open knives, moving up the scraper, cleans the NCT.

The diameter of the knives in the working position is calculated taking into account the necessary clearance between the knives and the walls of the pipe. For NCT 73 - a diameter of knives 56 mm, for NCT 60 - a diameter of 44 mm. Thanks to this, jamming is excluded during cleaning, but at the same time, already during the first passage in most cases, the passing diameter of the TCT increases to the maximum possible working condition of the oil -containing fluid duct.

Methods of ARPD removal - comparative characterisation

Operating procedure

- 1The mechanism for attaching the scraper to the wire is via a ropsocket (using a bell or roller) as part of the lowering device (winch).

The scraper is lowered inside the string by gravity to a depth below the cleaning zone. - 2When the pig reaches the set mark, the device (winch) is switched to start lifting, and the pig, rising, removes paraffin from the surface of the tubing string. In the process of pig lifting, the cleaned deposits remain in place, not creating problems during further cleaning. The tubing string is flushed either during or after the cleaning procedure.

Technical characteristics of sliding scrapers

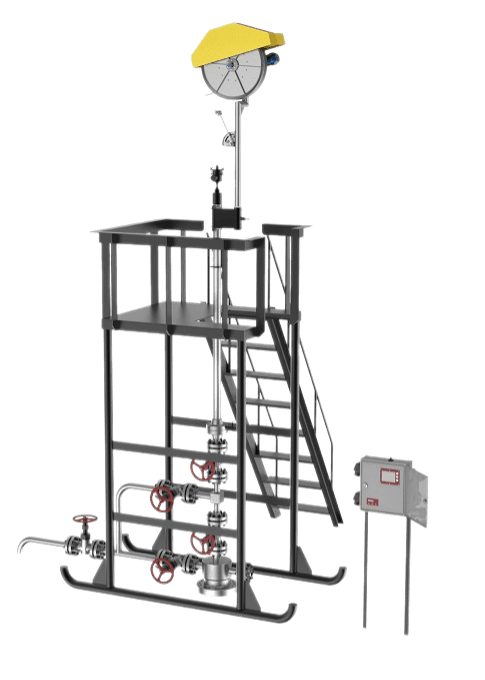

Well dewaxing equipment

Photo gallery of sliding scrapers

FAQs

The warranty period for SR-Techno scrapers is 12 months from the date of sale.

SR-Tekhno sliding scrapers are designed for cleaning 60/73/89 mm tubing.

To order equipment and consult with our experts, you can contact us by phone, email or fill out the feedback form on our website. Our team will be happy to help you find a solution optimised for your needs.